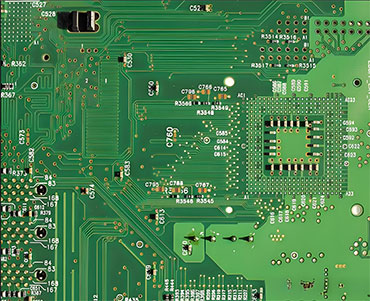

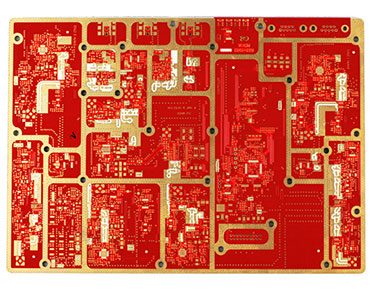

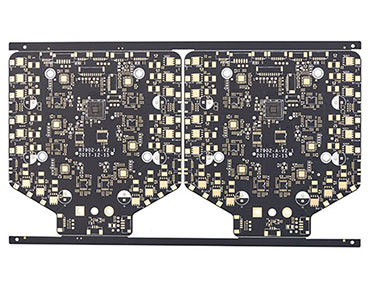

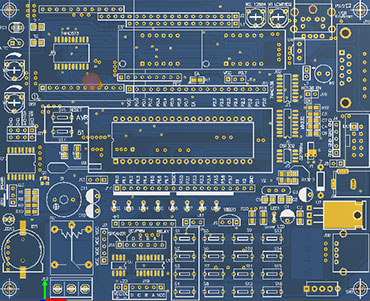

PCB named circuit boards

The material of printed circuit board (PCB) should be selected based on the specific requirements of the electronic device being produced,like fire retardant, dielectric constant, loss factor, tensile stability, glass transition temperature, and Z-axis expansion coefficient. There are quite a few different dielectrics that can be chosen to provide different insulating values depending on the requirements of the circuit.

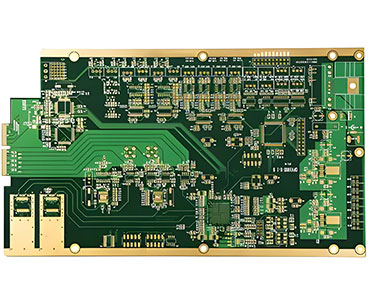

Thermal expansion is an important consideration especially with ball grid array (BGA) and naked die technologies, and glass fiber offers the best dimensional stability.

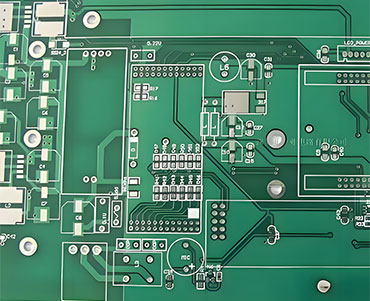

FR-4 is by far the most common material used today. The board stock with unetched copper on it is called "copper-clad laminate".

Common materials of PCB boards are used in Light PCB boards are CEM-1, CEM-3, FR-4, aluminum, and copper alloys.

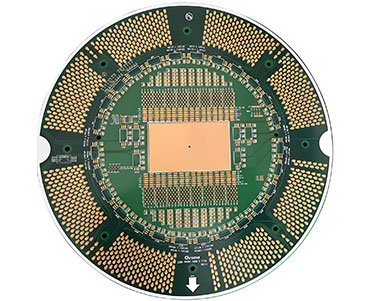

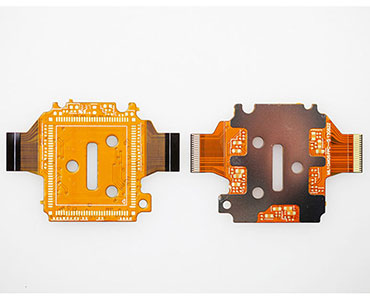

As a Ceramic PCB manufacturer in China, we can provide the ALN(Aluminum oxide) and AIO203(Aluminum Nitride) Ceramic PCB with ENEPIG, ENIG, Immersion silver surface. Ceramic PCB is actually made of electronic ceramic materials and can be made into various shapes.

The ceramic circuit board has the following characteristics: high-temperature resistance, high electrical insulation, low dielectric constant, low dielectric loss, high thermal conductivity, good chemical stability, and thermal expansion almost can be coefficients of components.

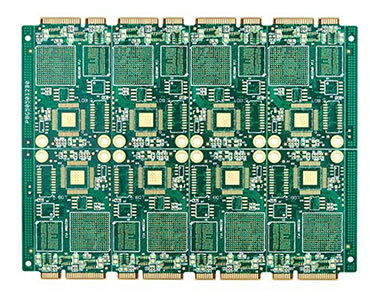

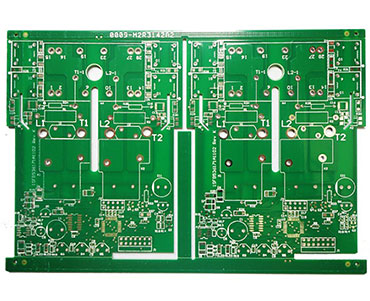

Copper Coin printed circuit boards are used for various products, such as in planar transformers, planar transformers, power converters, etc.

High Power Distribution Planar Transformers Heat Dissipation

Power Converters Amplification Systems Solar Panel Manufactures

Power Controllers Welding Equipment

RO4350B+Fr4, board thickness 0.032″, ENIG High-speed connectivity between multiple circuits.

Its high thermal conductivity means it can transport heat better and evenly.

The copper coin for PCB also ensures high heat dissipation with better control and even distribution.